You heard it a million times as a kid: “Close the door or you’ll let the heat out!” These early attempts at teaching you responsibility have a very practical effect, so hopefully, you listened.

In the past few months, we’ve discussed where you should target maintenance and inspection for your commercial and industrial building or facility, with a focus on cold storage facilities. After decades of client projects, these are the most common areas we’ve seen building components fail and cause damage:

- Vapor barriers

- Condensation

- Door Seals

Along with vapor barriers and areas of condensation, door seals cause owners the biggest headache. From creating temperature fluctuations in cold storage to increased energy bills in commercial businesses, most owners underestimate the impact of faulty door seals.

Why Door Seals Fail

Doors are placed where they are for a reason: an access port between two areas is needed. Their very nature means they often see a lot of use, and even doors that aren’t used that often can still have failing components.

Your most used doors, however, are the obvious point for the most common failures. Office building front doors, for instance, often cause building owners increased energy costs and are overlooked for thorough maintenance.

You can’t avoid wear on doors and their parts — a building is barraged from the moment it’s constructed. The sun damages buildings and UV light can penetrate deeply into components and cause wear and damage. Cleaning agents and cold temperatures can damage rubber and other materials used for door seals.

As the Certified Commercial Property Inspectors Association points out, preventive maintenance is the best way to avoid costly repairs, but “predictive maintenance” is also important. Predictive maintenance refers to repairs and maintenance performed because the building needs it, as areas of wear are discovered during an inspection.

Docking bays and loading dock doors in commercial distribution and manufacturing facilities often receive a lot of mileage without proper inspection and replacement. Particularly with cold storage facilities, leaking docking bays can be the first step in a product flow with more leaks than a sinking ship.

The main point, however, is that door seals fail for two basic reasons:

- Unavoidable damage

- Unrepaired damage

A proper building inspection and maintenance routine is vital for all buildings.

What Should You Look for During Building Inspection?

Every facility needs a good maintenance and inspection schedule, and commercial and industrial cold storage maintenance specifically should be done competently and place a high level of emphasis on leaking doors. Annual inspections should be the minimum for your facility.

Broken and cracked door seals are the most obvious problem and a visual inspection should be your start. Have you noticed higher than normal energy costs? Are you having frost form around freezer or cold storage doors?

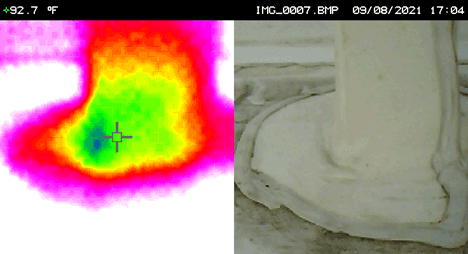

Not all leaks are visible to the naked eye. In our professional inspections, we employ thermal imaging. You can read about it more in-depth here, and this example photo shows how we use thermal imaging to locate areas of heat transference.

This image shows a pipe leaving a freezer room. The color should be more uniform, and blue areas are the coldest areas and are barely visible here. Looking at this image, we would know that this is a major weak point in the system because, at 92 degrees, it’s way too hot.

What Can Failing Door Seals Cause?

An improperly sealed door allows air to travel from one side of the door to the other — which, especially in climate-controlled and cold storage facilities, can have devastating effects. Commercial, retail, and office buildings should also be mindful of door leaks, however.

Leaking air is leaking money. The National Institute of Standards and Technology agrees that building envelope leaks waste utilities and creates larger energy bills. As you were warned when you were a kid, stop letting all the air out!

What Can You Do About Failing Door Seals?

Repair or replacement is your only option for faulty door seals. It’s not as easy as running down to the nearest home improvement store and buying some weather-stripping, though.

After thorough and careful inspection, the proper seals and materials need to be used. Our teams of experienced professionals use this time to choose materials that offer an improvement over the previous materials, if available.

When repairing door seals for clients, our teams also make sure the newly installed seals perform up to par. This extra layer of quality assurance keeps our clients’ energy bills low and their cold storage freezer room temperature stable.

We’re here to help. Our experienced crews can inspect your facility and our in-depth consultation helps you decide what repairs and maintenance your business needs. As a Butler Builder®, we’ll help you repair your current facility and expand into a new, efficient facility if you need to.

If you need a partner for your next project or an expert consultation about your current facility, contact GALBRAITH today.