It’s a fact: yearly inspections and maintenance schedules help owners avoid unexpected expenses. A well-staffed maintenance department, with a well-funded expense account, can keep a metal building system running for a long, long time.

After all, metal buildings don’t rust, rot, mold, or fall prey to termites. We’re not saying your metal building system is guaranteed forever, just that preventive and predictive maintenance is key to a building that can stand the test of time.

Not everyone has a maintenance team. GALBRAITH offers full building maintenance services, but sometimes you just need to know where to look and what to look for — and when to call in professionals for help.

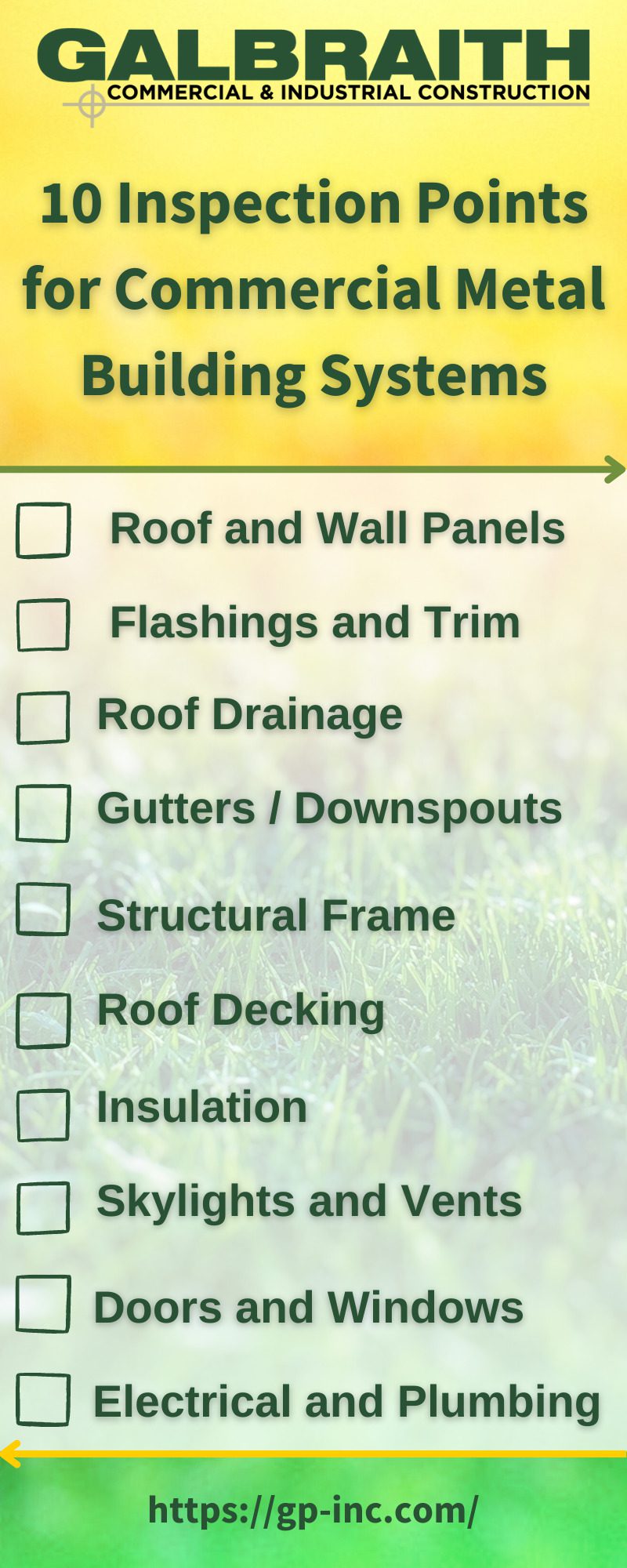

We’d like to make it a little easier for you. We’re going to discuss the 10 points a commercial metal building system owner should never fail to inspect, and we’ve included a checklist you can use to assure your building is getting the preventive maintenance it needs.

The Basic 10 Inspection Points for Commercial Metal Building Systems

Roof and Wall Panel Condition

Let’s start at the top! Your roof is often your first line of defense against the elements. It also works to keep cooling and heating in or out, whichever you might need.

We’ve discussed how important the vapor barrier inside your roofs and walls is, and the need for thoroughly inspecting it. We can’t stress enough that vapor barriers in roofs and walls are one of the most common areas of failure!

Maintenance teams should thoroughly check for any dents, cracks, rust, or other signs of damage. Got a drone at home? Take the legwork out of the chore by using a drone for roofing inspections then zeroing in on problem areas for further analysis.

Make sure that the roof and wall panels are properly secured to the frame. Your wall system works in tandem to create an envelope of weathertight protection and should be thoroughly inspected for damage.

Flashings and Trim

Flashings and trim protect your building from water and wind damage. Flashings are metal pieces that are installed at intersections between roof panels and walls, as well as around roof penetrations, to prevent water from seeping into the building.

Trim refers to the materials that are used to finish the edges of the building’s roof and walls, including trim pieces around doors and windows, and at the top and bottom of the walls. The flashings and trim help to create a tight seal around the building, preventing water and wind from entering, and protecting the interior from water damage.

Inspect the flashings and trim for any signs of rust or corrosion, and check for proper installation and sealing. Due to their nature and often hard-to-reach locations, this is often overlooked in building maintenance routines.

Roof Drainage

Moving water, snow, and ice off your roof is a full-time job, and there are a few dedicated systems in place for the task. Once again from the top down, we’re starting with your roof drainage system.

A properly functioning roof drainage system prevents water from pooling on the roof, which causes leaks, damage to the roof decking, and mold growth. Also, the roof drainage system helps prevent water from entering the building through cracks and gaps in the roof and walls.

Check the roof drainage system for proper functioning and clear any blockages you find.

Gutters and Downspouts

Moving downwards from roof drainage, your gutters and downspouts should be inspected next.

Make sure they are free from debris, properly secured, and directing water away from the building. Commercial gutter systems are often heavier duty than residential gutters and downspouts. This doesn’t mean they can be ignored, however.

Structural Frame

Inspecting the structural frame of a metal building system doesn’t create the anxiety of a wood-framed structure inspection, but it should still not be a skipped step.

Metal building systems do not rust, rot, mold, or fall prey to pests like termites. This seeming impenetrability is still only man-made, however. Inspect the structural frame for any signs of corrosion, rust, or damage, and make sure it is securely anchored to the foundation.

You don’t want to end up like the Leaning Tower of Pisa.

Roof Decking

Speaking of foundations, you also need to check the foundation of your roof: the roof decking.

Located under the metal panels, below the vapor barrier and insulation, lies the roof decking. Installed on the structural roof deck of a commercial building, decking provides a flat and solid surface for the roofing system installation.

Made of concrete, wood, metal, or a combination of these materials, roof decking is designed to withstand the weight of the roofing system and the elements: wind, rain, and snow.

Check the roof decking for any signs of water damage, warping, or other structural issues. Ensure fasteners are secure and in good condition and check seams and joints while you’re looking.

This is a great time to verify fire safety measures and materials are in proper working order and to check for the presence of excess moisture — that could point to issues with ventilation.

Insulation

Inspect the insulation for proper installation and any signs of damage, and make sure it is adequately protecting the building from heat and cold. Visually check for gaps between insulation segments and other areas of weakness.

We often use heat imaging, as you can see here, to test for areas of insulation failure or other instances of heat or cold loss. Other inspection points include measuring the insulation for consistency and compliance and visually inspecting the insulation for areas where it does not contact the surface or has water damage.

Skylights and Vents

Skylights can increase creativity and boost your mood. They also create a weak point in your structure. The benefits of skylights create tempting energy savings for business owners, and you shouldn’t let the added inspection time turn you from their usefulness.

When inspecting, check skylights and vents for proper operation and any signs of damage or leaks. The flashing and trim around the skylight also need to be scrutinized and note any failing weather-stripping.

Doors and Windows

We don’t care if this is beating a dead horse: check your door seals and windows!

In the past, we’ve stressed the importance of door seals and cited them as one of the leading areas of failure in commercial buildings. Doors especially are the most often used components of a building.

Inspect doors and windows for proper operation, proper sealing, and any signs of damage. Cold storage facilities and other commercial buildings with climate-controlled environments cannot neglect this step.

Electrical and Plumbing Systems

Electrical and plumbing systems are crucial to the safe operation of your building. Increased regulations and code compliance also mean that a good maintenance schedule will save you future headaches.

Check the electrical and plumbing systems for proper operation and make sure they are up to code and in good working condition. Call in professionals for a thorough inspection if your team lacks the required knowledge or credentials.

The Importance of Inspection and Maintenance

Even if everyone performed building inspections and all the required maintenance, buildings would still require repair, and accidents and equipment failures would still occur. Routine inspection and maintenance work to lessen the financial impact of owning or operating a building.

GALBRAITH’s team of professionals brings “The GALBRAITH Difference” to your next repair or new construction project. Our honest, experienced analysis of your building will help you find problem areas, correct them, and save some money along the way. Using our connections as a Butler Builder®, we’ll help you maintain your facility with industry-leading parts and systems.

Contact us for more information, to schedule a consultation, or to discuss building maintenance issues.